- >

- Superconductivity

- >

- Superconductivity Application Technologies

- >

- Superconducting Wires

Superconducting Wires

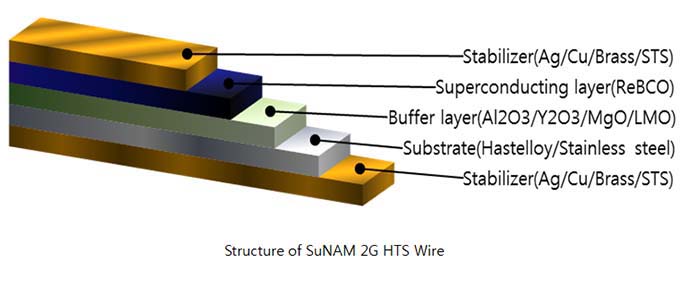

It is a tape typed coated conductor (CC) wire and the wire constituted of multi-layers which have metal substrate, buffer layers, ceramic high temperature superconductor (HTS) and stabilizer. In general, the current with critical current density of more than 1MA/cm2 can flow without any loss of resistance in HTS. The wires are applied to the most of superconductivity application devices such as superconducting cables, motors, generators, transformers, power storage devices, etc.

Technology for Metal Substrate Manufacturing

Thin, and high strength metal substrate is manufactured to impose flexibility and toughness against mechanical deformation of ceramic HTS superconductors. Then the substrate is processed like clean mirror surface.

Technology for Epitaxial Growth Buffer Layers Manufacturing

Metal substrate is sputtered with high epitaxial growth buffer layers in order to improve the performance of superconducting layer. The manufacturing of superior epitaxial growth buffer layers with high speed is a key technology.

Technology for Superconducting Layer Sputtering

High current density in superconducting layer is increased with more excellent sputtering characteristics of superconducting layer. Thus it is a core technology to determine the performance of superconducting wire. In order to improve the conduction characteristics, magnetic flux anchor is sometimes artificially injected.

Technology for Stabilizer Formation

Stabilizer is coated for a bypass of current and to improve the mechanical strength, when quench is generated in superconducting layer during current flow.

| Technology Characteristics |

Non-resistance

DC current can flow without power loss because of no electrical resistance.

High-density current transport

Amount of current flow without power loss per unit area at liquid nitrogen temperature is more than 1MA/cm2. That represents the best characteristics amongst existing materials. The performance of the equipments with a variety of superconducting applications can be improved by utilizing the best electric characteristics.

Low-cost cooling

Unlike existing low-temperature superconducting wire, cooling is done using low-cost liquid nitrogen. Thus cooling cost is significantly reduced and commercialization is very favorable because limitless nitrogen in the air is utilized.

Primary Superconducting Applications

Most applications of superconducting devices such as superconducting cables, motors, generators, fault current limiter, transformer, power storage devices, etc. are essential. Performances of the equipments are largely dependent on the performance of superconducting wire.

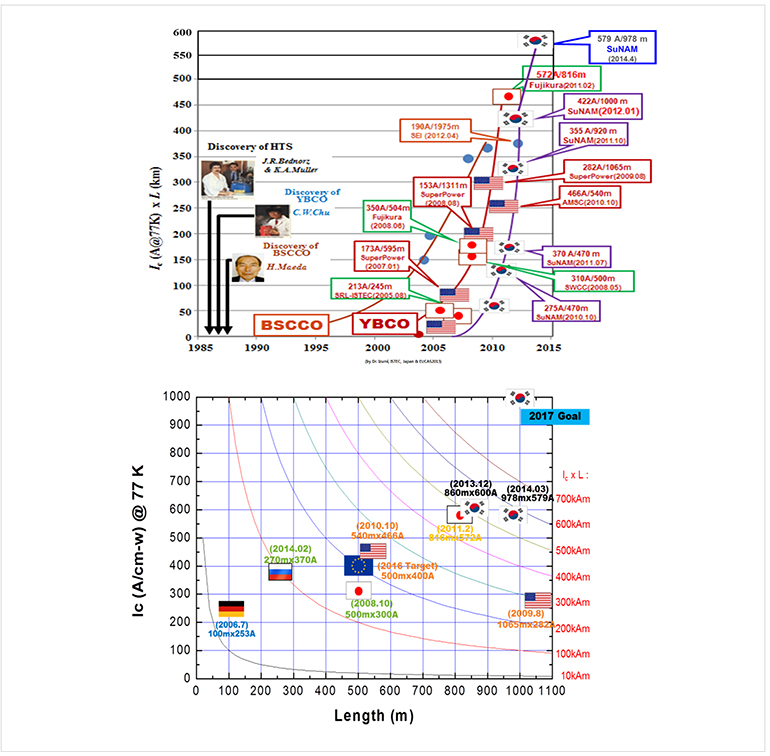

| Development Trends and their Levels |