- >

- Superconductivity

- >

- Superconductivity Application Technologies

- >

- Superconducting Rotating Machine

Superconducting Rotating Machine

HTS motors or generators are manufactured by using high-temperature superconducting magnet and thus the efficiencies of motors and generators are increased and the weights are decreased so high efficiency and environmentally friendly power and electricity generations are possible.

Technology for Superconducting Rotating Machine

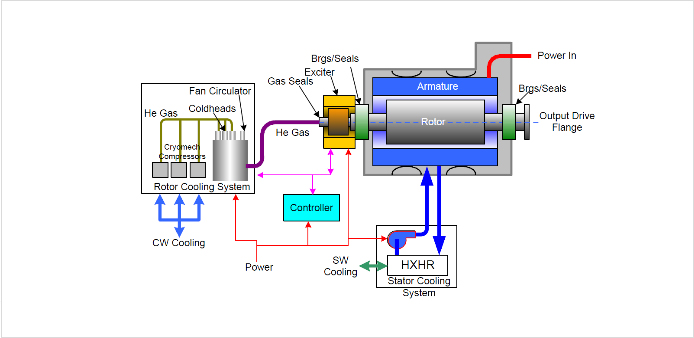

Design and manufacturing technology of HTS rotor includes the HTS magnet optimization, design of bobbin structure and torque tube.

Technology for Cryogenic cooling

Neon re-condensing system, helium forced circulation system, the refrigerator mount system and efficient and reliable cooling system.

Technology for Performance Evaluation

Rated test for motors and generators, long-term reliability assessment and cooling performance evaluation.

Technology for Application to the Real Power grid Operation of Superconducting Generator

Power grid operation, control and maintenance technology of HTS generator

| Technology Characteristics |

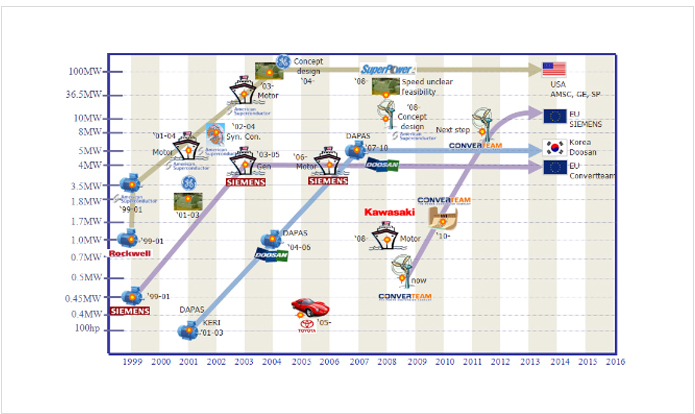

Light Weight and Large Capacity

The weight and size of superconducting rotating machines can be reduced dramatically by using superconducting magnets. Large capacity superconducting offshore wind turbines are especially possible for a capacity of 10 MW or more. In large capacity equipments, they are gearless type and do not use gear box. Thus long-term reliability of the system is increased significantly.

Low Loss and High Efficiency

Losses can be reduced down to 67% and efficiency can be increased by 2%, compared to conventional motor.

Eco-friendly

The risks of overheating and insulation breakdown can be reduced by using a highly insulated air-core typed armature.

| Development Trends and their Levels |