- >

- Superconductivity

- >

- Superconductivity Application Technologies

- >

- Superconducting DC induction furnace

Superconducting DC induction furnace

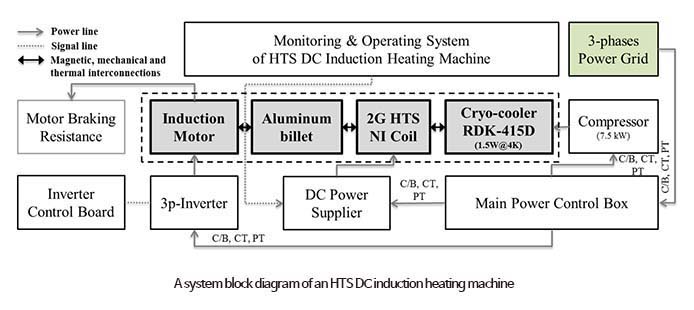

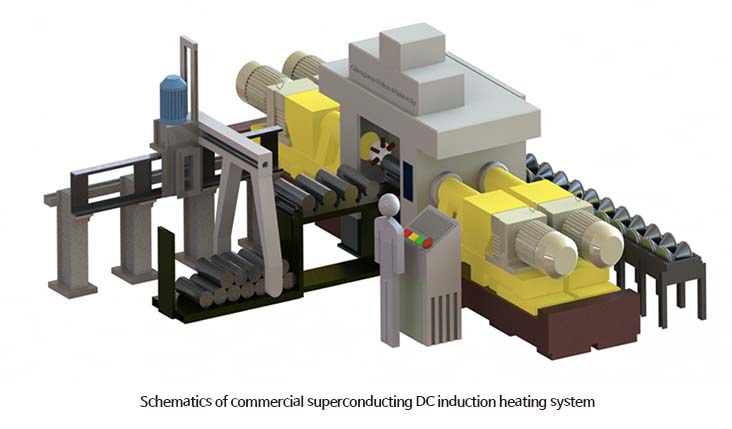

The process of DC induction heating method using HTS magnets is to heat a rotating metal billet under a uniform magnetic field generated by lossless superconducting magnets.

It enables one to achieve a heating system energy efficiency of 80–90%.

This heating machine is basically composed of three parts: HTS NI magnets with a conduction cooling system, a rotating system to rotate an aluminum billet and a monitoring and operating system.

| Technology Characteristics |

High efficiency

This technology leads to the energy efficiency around 80–90% in a large capacity of heating system using superconducting technologies.

Independent system

It does not create power quality problems in the grid because it uses an independent DC power supply.

High quality

It has a very small temperature deviation with a controllable rotating speed.

High productivity

The productivity per hour of an HTS DC induction heating machine is much higher than that of the conventional AC induction heating method.

The amount of active power available for heating a metal billet increases in the equivalent capacity by minimizing energy losses.

High availability

Various objects could be applied and operated in a machine without any additional device or function as well as with the best heating quality through easily controllable magnetic field.